Automatic Fuel Ethanol Plant

Product Details:

- Condition New

- Power 75 kw Watt (w)

- Product Type Automatic Fuel Ethanol Plant

- General Use Industrial

- Material Other

- Computerized No

- Automatic Yes

- Click to view more

Automatic Fuel Ethanol Plant Price And Quantity

- 1 Plant

- 100000000 INR/Plant

Automatic Fuel Ethanol Plant Product Specifications

- Low Energy Consumption

- Yes

- 75 kw Watt (w)

- No

- Automatic Fuel Ethanol Plant

- 75 kw Watt (w)

- New

- Other

- Planetary

- Electric

- Industrial

Automatic Fuel Ethanol Plant Trade Information

- Cash Advance (CA) Cheque

- 100 Plant Per Month

- 90 Days

- All India

Product Description

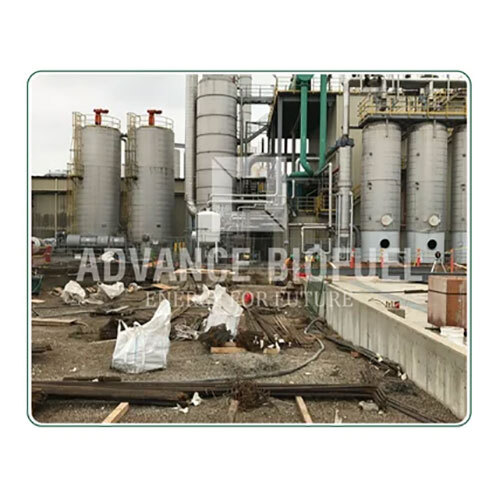

Automatic fuel ethanol plant contributes in making ethanol by using corn sweeteners as the main product of wet-mill plants, along with a number of other co-products. Starch, protein, and fibre in corn are separated using wet mills before being used to make ethanol.

Automatic Fuel Ethanol Plant is used for making fuel for vehicles. It is based on latest molecular sieve technology that features options like three bottle pressure swing adsorption which allows smooth transition and longer sieve life. This plant is designed and manufactured using optimum grade material and emerging techniques under the visionary supervision of trained professionals. Our clients can avail this Automatic Fuel Ethanol Plant from us in different specifications at market leading prices.

Specification

- Minimum Order Quantity: 1 Piece

- Capacity: 10, 20, 30,40,50, 60, 100 KLPD

- Automation Grade: Automatic

- Power Consumption: 75kw

- Design Type: Standard

- Frequency: Regular

- Material: ms and ss

- Operating Voltage: 75 kw

- Raw Material: Agriculture

- Surface Finishing: biofuel

- Voltage: 75 kw

- Weight: 20 mtr

- Country of Origin: Made in India

FAQs of Automatic Fuel Ethanol Plant:

Q: What is an Automatic Fuel Ethanol Plant?

A: An Automatic Fuel Ethanol Plant is a specialized industrial facility used to produce ethanol fuel from various feedstocks such as corn, sugar cane, and other grains. This type of plant uses a combination of mechanical, chemical, and biological processes to convert the feedstock into ethanol fuel.Q: What are the features of an Automatic Fuel Ethanol Plant?

A: An Automatic Fuel Ethanol Plant features low energy consumption, a planetary mixer, electric drive type, and a voltage of 75 kW Watt (w). It is fully automated and does not require a computer to operate.Q: What is the condition of an Automatic Fuel Ethanol Plant?

A: An Automatic Fuel Ethanol Plant is brand new and has never been used before.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+